The pump jet on a DCNS Triomphant class SSBN. Note the H-plane tail which aids stability when the sub is firing its ballistic missiles . A similar but smaller version of the DCNS pump jet may be going on the Barracuda SSN and eventually the Shortfin SSK.

---

Since writing Shorfin’s Pump Jet Propulsor - A Sales Feature of April 29, 2016, I’ve been puzzling about what is technically new to make a pump jet viable on an SSK viable.

A central problem is that there is a correlation between pump jets and large nuclear submarines. Only companies (or countries) that developed pump jets for nuclear subs were in a position to then develop them for SSKs.

Until recently the weight of steel or other metal alloys may have made a pump jet too heavy for a Barracuda (at the smaller end of the SSN scale) or the Shortfin large SSK derivative. Still further lightening may be necessary before a pump jet is viable for Shortfin.

From looking at the sources in the BACKGROUND (below) it seems that using Nickel Aluminium Bronze alloy and/or epoxy fibre composite for a pump jet's rotor shaft, rotors, stators and the duct/shroud has many advantages including

- providing a better power to weight ratio for the sub

- not unbalancing the sub

- a fully composite duct gives off a minimum magnetic signature

- composite duct also reduces acoustic signature

- pump jets are low maintenance

A rotor (brown) and stator (dull silver) can be seen in this Mark 50 torpedo pump jet.

BACKGROUND

The Behavior of Structures Composed of Composite Materials, 2006 indicates:

[Page 27] Although recent designs of composite propeller systems is classified, the use of modern composites manufacturing allows for continuous fibres to be aligned with major hydrodynamic and centripetal forces. …The use of composites is now is now being introduced for propeller shafts on large ships (frigates and destroyers) where they account for 2% (100-200 tons) of total ship weight.

Carbon fibre/epoxy and glass fibre epoxy composite shaft shave the potential to be 25-80% lighter than steel shafts…while also providing noise suppression…thus reducing…acoustic signature. Also the non-magnetic properties of composites reduce that signature.”

This 2008 paper for the UK Royal Institution of Naval Architects on page 1 explains meaning of composite:

“A composite material is a material that consists of two components: the fibres and the matrix…The fibres are the part of the composite material that contributes to the strength whilst the matrix holds the fibres together.”

See Rolls-Royce website on the benefits of pump jet propulsor for the Astute SSNs.

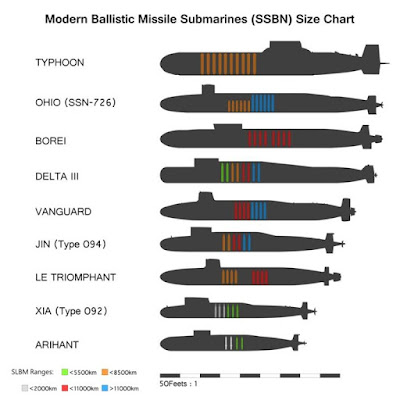

As can be seen above several nuclear subs lack pump jets because they lacked (or lack) pump jet technology. It seems pump jets cannot be retrofitted. (SSBN diagram courtesy pinterest)

---

Pete